Despite CNC machining being a long-standing presence in our lives, it’s surprising that some people remain unfamiliar with this manufacturing process. Have you ever wondered how companies acquire intricate machine parts? The answer lies in CNC machining.

This process extends beyond machine parts and serves as a crucial manufacturing technique for individuals seeking hands-free production. If you’re new to the world of CNC machining, we understand that you may not be fully prepared. That’s why we offer CNC Machining Basics, providing you with the foundational knowledge of this process.

What Is CNC Machining?

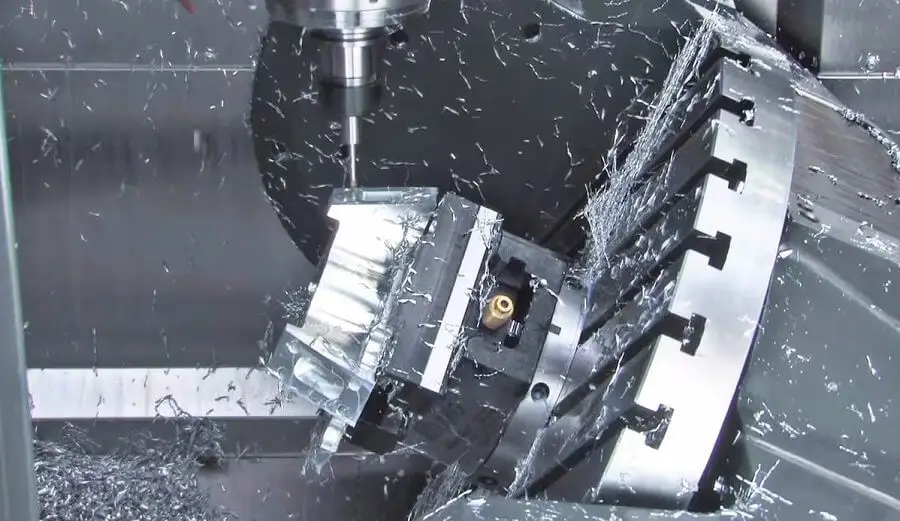

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is until the material forms the input designed part.

How CNC Machining Works?

In order to further grab the basics of CNC machining, it is crucial to know how CNC machining works. From the definition, CNC machining is a subtractive and computerized process. Therefore, knowing how it works comes from understanding the relationship between the computer, the required operations, and the workpiece.

Based on this relationship, CNC machining’s mechanism can be divided into four different stages, which we explained below.

- Create A CAD Design

Creating a Computer-Aided Design either in 2D or 3D format is the first thing to do. You can achieve this by using CAD software. With the software, you can render any parts you want with the right technical specifications. However, there is a little limitation. The workpiece’s properties have a huge role to play in the design and how it turns out. We will discuss this under CNC machining materials.

- Convert the CAD File to A CNC Program

The next step is converting the CAD file to a CNC-compatible file format. The CNC program will analyze the CAD file to generate the programming codes needed for the process.

There are two types of code you should be familiar with in CNC machining basics. These are the G-code (Geometric Code) and M-code (Machine Code). G-code controls the machine’s actions. For example, it controls how it moves, when it moves, how fast it moves, the path it takes, etc. On the other hand, the M-code controls the factors that surround the machine’s capabilities. For example, it controls the removal and replacement of the machine cover.

- Set Up the CNC Machine

Setting up the CNC machine is done in two ways. One is that you must run a check on the CNC machine to ascertain its condition. The second thing is fixing the workpiece on the machine. You can fix the workpiece directly into the machine while you attach the required tools and components.

- Execute the Operation

After setting up the CNC machine, you can then run the CNC program. The CNC program is the control center for all the actions of the CNC machine. It commands the machine by dictating its actions and movements toward getting the right result.

Modern CNC machining like ours at Rapid Direct only requires you to upload a CAD file. The CNC program will analyze the CAD file to make sure the design is possible.

Common CNC Machining Operations

Understanding CNC machining operations is essential to grasp the full concept of CNC machining. There are two significant operations that you need to be aware of, and we will demystify them for you below.

CNC Milling

Milling in CNC machining is cutting away part of a workpiece using rotating cutting tools.

There are two processes in CNC milling. The automatic process allows a CNC machine to feed the workpiece directly into the cutting tool rotation. The feeding direction is always in the direction of the cutting tool’s rotation. The other is manual CNC milling, which is always the opposite of the cutting tool’s rotation.

CNC Milling allows you to perform two major types of operations:

- Face Milling: This is used for cutting shallow surfaces, flat surfaces, and flat-bottomed cavities.

- Peripheral CNC Milling: This is for cutting deep cavities on the workpiece.

CNC Turning

In CNC machining, turning refers to the process of removing material from a workpiece while it rotates on a single axis. The definition may sound complex, but let’s simplify it with an example. Imagine a bolt and a nut. CNC turning is the process of creating the spiral external and internal parts of these two components using CNC machining.

CNC Turning allows you to perform the following operations:

- Boring.

- Facing

- Grooving.

- Thread cutting.

Depending on your CAD file and specific requirements, there are other available CNC machining operations to consider. Below, we outline some of these additional options for you to explore.

- Drilling.

- Broaching.

- Sawing.

- Grinding.

- Honing.

- Lapping.

Pros and Cons of CNC Machining

Understanding the basics of CNC machining involves recognizing its advantages and disadvantages, just like any other machining process. Here are some of the pros and cons of utilizing CNC machining.

Pros

- Precision

CNC machines are precise. Therefore, they are employed in sectors that deal with human lives. You wouldn’t want to board a plane made from materials subjected to a flawed manufacturing process. This makes them the right manufacturing process for the aviation, and automotive industries.

- Accuracy

CNC machines have high accuracy, which allows them to produce parts without worrying about whether they will fit into a bigger component.

- Versatility

CNC machining offers various options in terms of materials supported. You should know whether the material is compatible with the process before using it. Check for factors such as heat tolerance, sheer resistance, and hardness.

Cons

- Cost

Enjoying the pros of CNC machining comes with a very high cost. However, it is better to go on with it because of the advantages, such as accuracy and precision.

- Size limitation

CNC machining supports materials that can withstand the manufacturing process. However, there is a size limitation. This can lead to problems when manufacturing large parts.

CNC Machining Materials

CNC Machining 101 cannot be completed without knowing the materials suitable for the process. To be precise, you can use any material for the process. However, the material must be able to withstand the heavy requirements of the manufacturing process.

You can say that choosing a material for CNC machining depends on the material’s specifications and the manufacturing process. Examples of materials suitable for the process and supported by us at Rapid Direct are:

- Aluminum.

- Copper.

- Brass / Bronze.

- Steel.

- Stainless Steel.

- Titanium.

- Plastics.

- Wood.

You can find the full list of our supported materials on our instant quoting platform. Upload your design files and start your project today!